Customer Case

Control Towers of Ewals: all-around transport solution

How control towers create agile supply chains

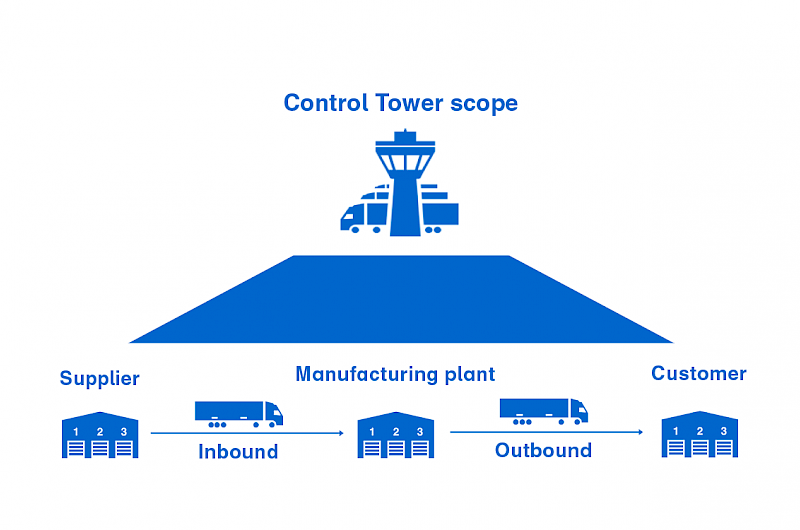

Supply chains are becoming more and more complex due to the increasing number of parties involved. Also, Covid-19, Ukraine, or oil crisis and other unexpected market developments have only increased the necessity for better visibility. Good risk management allows companies to avoid or minimize the impact of crisis situations. Yet, also proactively avoiding risks can result in additional economic value. The availability of control through data of all transport parties might predict, and optimize the regular supply chain processes, but also tackle possible disruptions. Supply chain visibility and control are fundamental to fluent supply chain flows and efficiency.

Connecting the dots for automotive supplier Auria Solutions

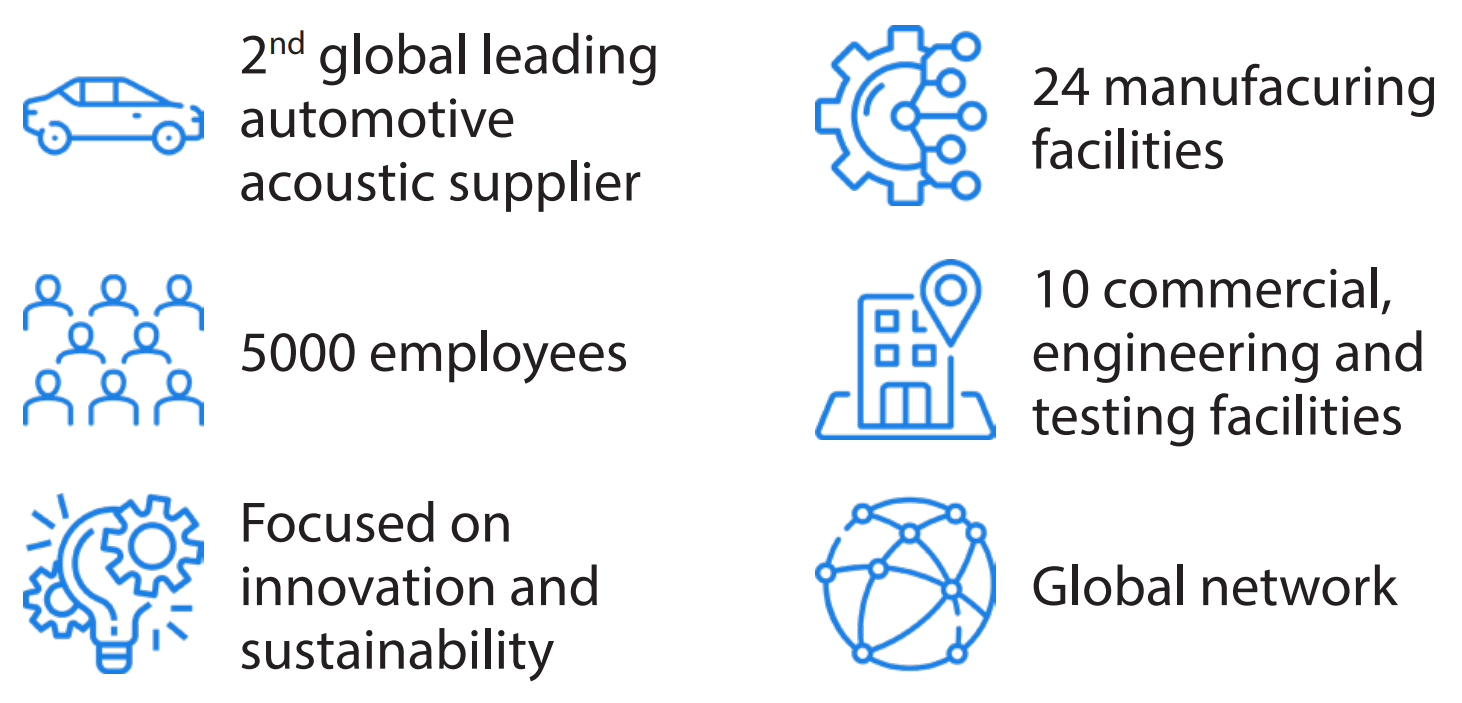

The benefits of Control Towers are well known to Auria Solutions. The company is the second biggest global supplier of automotive, acoustic and other fiber-based automotive products. Auria Solutions connects 24 manufacturing facilities and 10 commercial, engineering and testing and tooling facilities. Ewals team and its services are helping to ensure that all these facilities and its clients have the necessary resources to fuel their production and deliver end-products to clients. Since the implementation of Control Tower of Ewals in 2019, cooperation resulted in an outstanding 10% cost saving!

8 strengths Control Towers of Ewals brings to the table

What are 8 strengths that control tower can bring to a supply chain? Discover the benefits in interview with Auria Solutions - global leader in automotive acoustic supplies.

1. Choosing an easy implementation

Ewals Cargo Care and Auria Solutions were no strangers to each other. Thanks to the quality of transport services provided in the past, it was clear that there is an opportunity for even bigger cooperation. The next step to intensify the partnership was to transition from Ewals as a multimodal transport provider to a partner in supply chain optimisation by applying their control tower concept.

“We have chosen Ewals because we know their transport quality from past experiences. One major distinction of the Control Towers team of Ewals is proactivity and support during the implementation process.”

Markus Werra, Senior Manager Logistics Procurement - Auria Solutions

2. Understanding the customer

Understanding customers’ needs and trust is crucial when it comes to sharing operational data. At each step of the supply chain, clear visibility and reliability is important to not disrupt ongoing operations.

“Ewals absolutely understands our automotive industry. If the supplier is not part of the complete process, everything can collapse. Ewals learned about our business, way of working and all the sites of the supply chain to provide the best support. It provided not only what Auria wished to have implemented, but also searched for other beneficial opportunities and tailored the solutions to our needs.’’

3. Resilience in a dynamic market

With a large partner network of over 1000 carriers and own fleet of over 3400 trailers, Ewals is prepared for all scenarios. This leads to better flexibility, reliability, and capacity.

“As you know, there are capacity constraints on the market. I’m very delighted to have a good partner like Ewals who knows the business and all the different carriers European wide. With this knowledge in the background, I believe we are well prepared.”

4. Connecting efforts for a better tomorrow

Ewals’ expertise is rooted in over 100 years of experience in what it does. Being a long-term leader in the market, would not be possible if it were not connected with continuous improvement. This innovative mindset is what always keeps the company and its clients ahead in the market.

“What’s important is to have a good partner in place. Then the business is running smoothly. When that is in place, it is all about continuous improvement. Ewals ensures exactly that.”

5. One system for all tasks

Supply chains can be dynamic, and production plants are always at high-speed

efficiency. Therefore, Control Towers services are there to simplify and support

daily tasks. The simplicity of supply chain optimisation for clients lies within the

consolidation of all operations into one crucial process and system. Simple as that.

“Our plants are overloaded with daily tasks, so providing orders in a simple manner takes just a moment. This improves our productivity. With Ewals, IT systems are seamlessly connected and the communication is flexible and seamless.”

6. Continuous improvement

Control Towers team analyses all relevant supply chain data to fuel Auria’s growth and make data-based decisions. Each quarter, so-called Kaizen sessions are held, where, based on complex analysis, opportunities fromtapping into savings to discovering new way of working are discussed. Thanks tobusiness intelligence and a team of experts, Ewals can provide an overview of, for example:

- Market situation updates

- Ongoing business developments

- Foreseen and unforeseen costs per plant and lane

- Key performance indicators per plant and per carrier

- Proposed and executed carrier changes and updates

- Ongoing operational topics

- Invoicing statistics and claims

- Continuous improvement plans

- Tenders development and support

“I’m absolutely impressed and delighted to see continuous improvement. Ewals has its own team of experts, who always conduct excellent and complete analysis, which includes cost-saving triggers. For any lane from A to B we have a complete insight, and we understand both where we’re losing money and where we can save money. On top of this, it has some ideas about potential lane improvements, which we can discuss with our plant teams.”

7. Co-creation mindset

The team of Control Towers scales efficiency by out-of-the-box thinking and with a co-creation mindset beyond the transportation flows.

“If we have some ideas, Ewals is always open to listening to us and following up on different proposals. They give us additional insights, such as how to load materials in a different way to create additional loading capacity on the trailer. Another example is changing the delivery frequency from weekly to biweekly or the other way around. All factors are considered to increase efficiency and deliver cost saving. We can learn from these investigations and experiences and make data-driven choices and justifications.”

8. Always looking ahead

With over 100 years of experience with Ewals in the market, the company never stops developing. So far, the cooperation has been a tremendous success. Ewals is continuously improving through new trailer concepts, always renewing and expanding its own fleet, supporting subcontractors with Ewals Driver Academy programs and much more. The drive for providing value never stops.

“The continuous improvement team is cooperating very well with the other parties in the supply chain, such as suppliers. Ewals supports them in how they can provide additional value to Auria, such as raising awareness on the impact of the incorrect bookings or the most efficient way of loading. This is done through practical handovers, like manuals with pictures or technical drawings for the best insights and alignment of the parties. Ewals proactively extends its value in the supply chain and takes an advisory or educational role.”

Focus on your core business. Ewals does the rest

With the growth of companies, the growth of logistics complexity is paramount. This is why, the Control Towers team runs a modular set of services, from designing and optimizing logistics networks to reporting and business intelligence and tendering. Thanks to multiple areas of expertise, customers can benefit from a comprehensive solution.

Control Tower potential

By thinking outside the box, Ewals team analyzes all possibilities of cost reduction. For a start:

- X-dock consolidation

- Roundtrips

- Mutlimodal

- Triangular traffic

- Equipment choices

- Pick-up frequency

- Pallet exchange

- Trailer utilization

- Empty packaging management

- Changing cut-off time

- Leadtime reduction

- Forecasting

- IT integration

- Time slots

- Booking method

- Stackability

- Packaging design

- Retendering

Read more

Customer Success story Ferpinta

A Strategic Partnership Fuels Ferpinta’s European Expansion

Gold standard

We’ve achieved a Gold rating from Ecovadis, scoring 75/100 and placing us in the top 5% of all companies assessed.

Avoid common freight mistakes

Delays, damage, & high costs? Learn how to avoid common mistakes.

.png?width=1181&height=1181&name=Ontwerp%20zonder%20titel%20(8).png)

.png?width=1181&height=1181&name=Ontwerp%20zonder%20titel%20(6).png)