How did the Control Tower support Ineos at its first car launch?

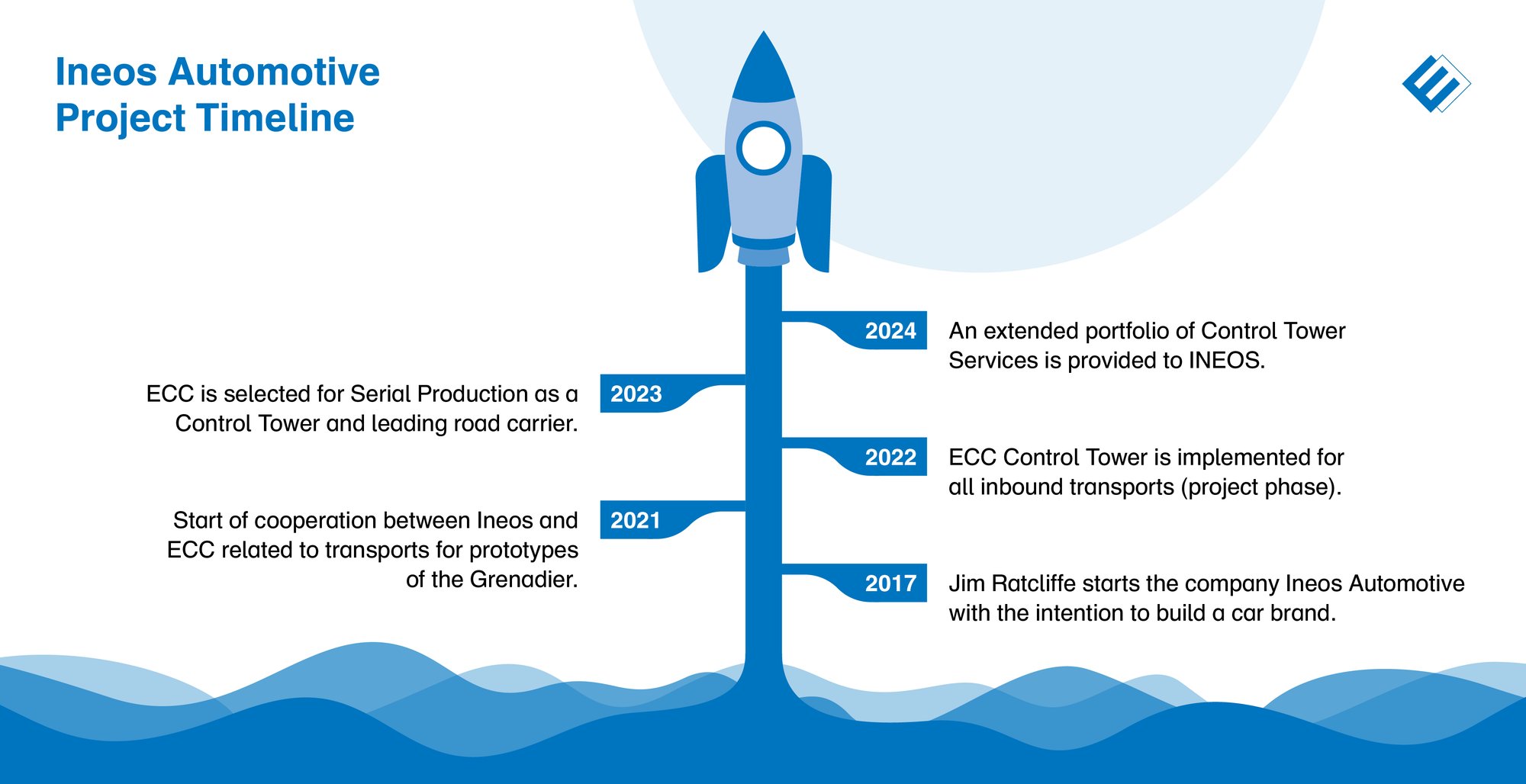

INEOS Group turned Jim Ratcliffe's 2017 vision into reality, creating the uncompromising Grenadier 4x4 with ECC's 100 years old transportation expertise. Together, we mastered complex automotive supply chains to achieve flexible operations.

.png?width=1080&height=1080&name=Turkey%20(14).png)

How it all started?

The vision of INEOS Group

Jim Ratcliffe, the visionary behind INEOS, had a vision. He envisioned creating a robust off-road vehicle — an Uncompromising 4x4 Grenadier. This dream led to the founding of INEOS Automotive. Turning this vision into reality required more than just ambition; it needed a team and partners who could navigate the complex world of automotive supply chains.

The beginning of a partnership

Our common journey began in June 2021 during the prototype testing and interior model reveal stages. INEOS was searching for experienced and creative control tower partners. ECC's Control Tower, grounded on over 100 years of transportation experience, provided the expertise, flexibility, and all-around support Ineos needed.

Overcoming challenges together

As INEOS Automotive moved forward with the Grenadier project, it faced several challenges.

- Complex Supply Chains: Automotive supply chains are inherently complex.

- Start-up phase: It needed a new ecosystem of suppliers, systems, and processes.

- Existing infrastructure: INEOS acquired an existing automotive plant in Hambach, France, which created opportunities but also infrastructure constraints.

Seamless transition

One of the significant turning points came when INEOS' previous transport provider suddenly stepped down. We needed to establish a transport operation and a control tower overnight. We rose to the occasion in this critical moment, bringing transportation expertise and innovative solutions.

Sr. Mgr. Supply Chain Engineering & Customs at Ineos

Operations

Building a successful supply chain

Our involvement went beyond transportation. We supported a network design to implement fixed routes, lead times, routings, and transportation modes. We also co-designed (customs) processes, provided consultancy, established execution of various modes of transport (road, ocean, air), and created data dashboards to ensure smooth operations and cost control.

‘’We value the expertise of ECC and its control tower. In my eyes, they do a really good job. (...) The strong advantage of ECC's Control Tower is the package of the various elements which we need for operational service and transportation."

- Björn Ibach, Sr. Mgr. Supply Chain Engineering & Customs at Ineos

Team and Operations

Dedicated team

ECC established a planning and logistics engineering team in the INEOS office in Porto to facilitate communication and integration. Our working operations ran from 5 a.m. to 10 p.m., with Saturday coverage, ensuring that the dynamic supply chain needs were met and supervised on time.

‘’It was unique that ECC was willing to set up operations so closely to our teams.’’ - Björn Ibach, Sr. Mgr. Supply Chain Engineering & Customs at Ineos

Customized systems

We customized our systems to work seamlessly with INEOS, such as Power BI dashboards and the Control Tower portal. This provided digital flexibility and insight into costs, transparency, visibility, and a baseline for easy communication.

’We find solutions to possible problems via daily communication. That's the key to this cooperation.'' - Fredrik Karlsson,

Head of Supply Chain Management, Ineos

Operational flexibility

We prioritize flexibility and adaptability, which are crucial for managing INEOS's fluctuating production and supply chain needs.

‘’Flexibility and adaptability were always the key to our cooperation. Also, the focus on cost awareness and cost improvement was really helpful." - Fredrik Karlsson, Head of Supply Chain Management, Ineos

ECC also took over processes such as carrier billing, claim processing, and reporting, showing the versatility of the services.

"We have outsourced all of our carrier billing processes to ECC, which is a huge workload." - Björn Ibach, Sr. Mgr. Supply Chain Engineering & Customs at Ineos

Success and future focus

Achieving success and looking ahead

With our support, INEOS Automotive produced its first Grenadier (Series Production) within three years. Currently, ECC’s Control Tower remains the leading company responsible for all inbound supply chain operations to Production Plant Hambach. The next step is to focus on CO2 reduction and more.

"ECC provides pragmatic solutions. So, it's not a very complicated process with ECC to find solutions that work for both of us. We don't have the time to spend days and weeks solving our issues, and we need fast solutions and out-of-the-box thinking. ECC provides just that.’’ - Björn Ibach, Sr. Mgr. Supply Chain Engineering & Customs at Ineos

Conclusion

The partnership between INEOS Automotive and Ewals Cargo Care has been a success story of flexibility, adaptability, and comprehensive support. Our expertise in managing complex supply chains and providing tailored solutions has supported INEOS in achieving its ambitious goals and continuing to grow in the automotive industry.

Why INEOS chose ECC’s Control Tower:

-

Expertise within Logistics

Practical expertise stems from 100+ year-old transportation background. -

IT Engineering Support

Using the end-to-end (order to cash) ECC TMS and customized reporting & dashboards to achieve control & visibility. -

Flexibility and Adaptability

Direct communication lines with the decision-makers allowed flexibility and adaptability. -

Pragmatic Solutions

We provided fast, out-of-the-box solutions suited for the start-up phase. -

Own Fleet

Our access to 4000+ trailers is an additional backup and carrier possibility.

.jpg)

Read more

Customer Success story Ferpinta

A strategic partnership fuels Ferpinta’s Industrial European expansion

Ecovadis Gold standard

We’ve achieved a Gold rating from Ecovadis, scoring 75/100 and placing us in the top 5% of all companies assessed.

Cutting costs for Auria Automotive Solutions

Control Towers boost Auria's supply chain agility with real-time visibility and proactive disruption management.

.png?width=1181&height=1181&name=Ontwerp%20zonder%20titel%20(8).png)

.png?width=1181&height=1181&name=Ontwerp%20zonder%20titel%20(6).png)

.png)